For the replacement of technical foams, Hexaflex is the solution of the future

Hexaflex in 2 words :

Innovative and efficient

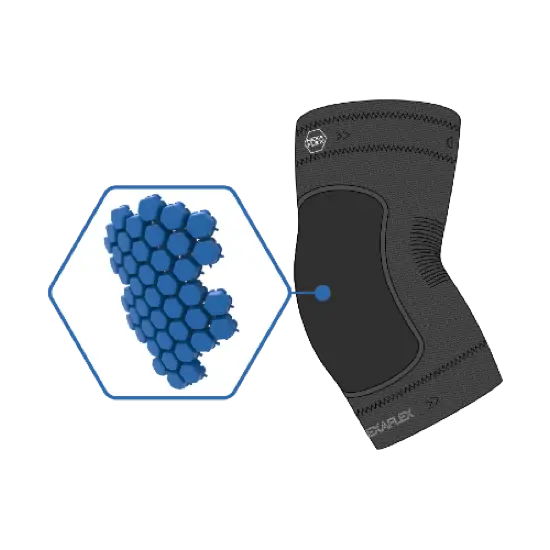

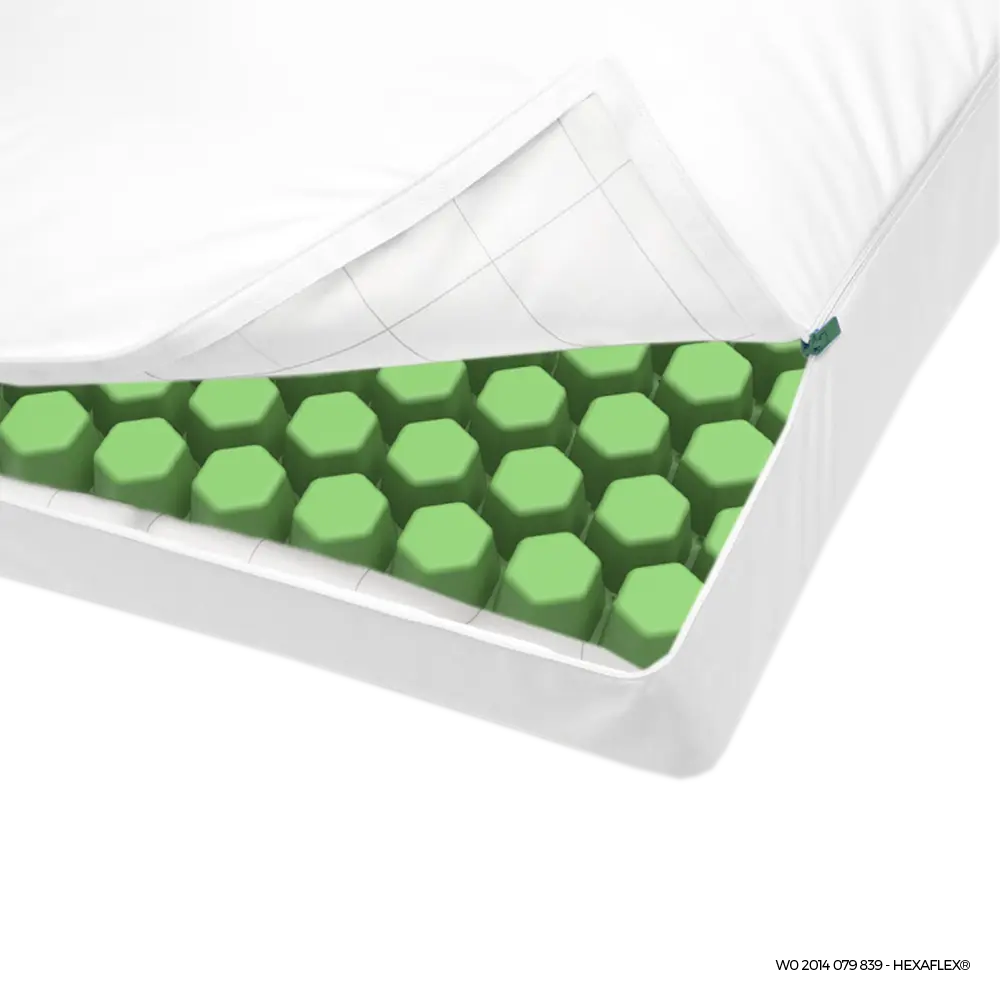

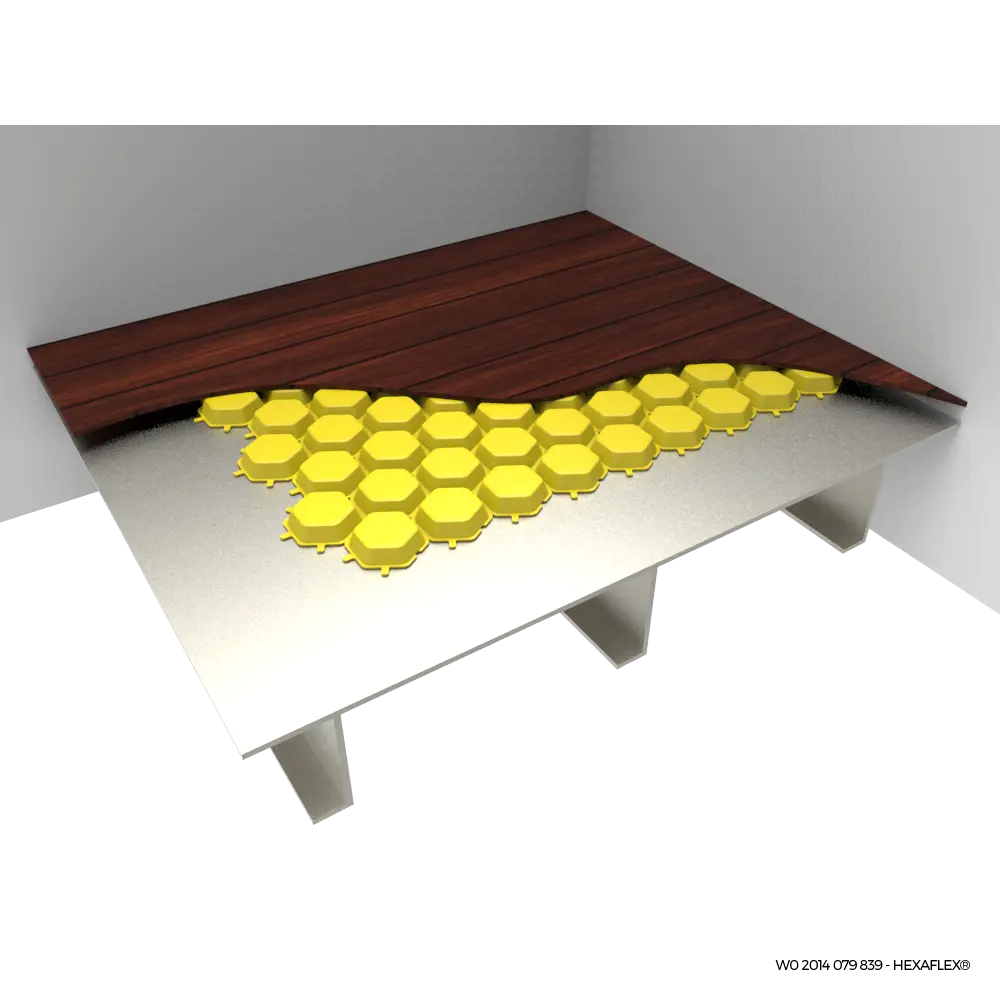

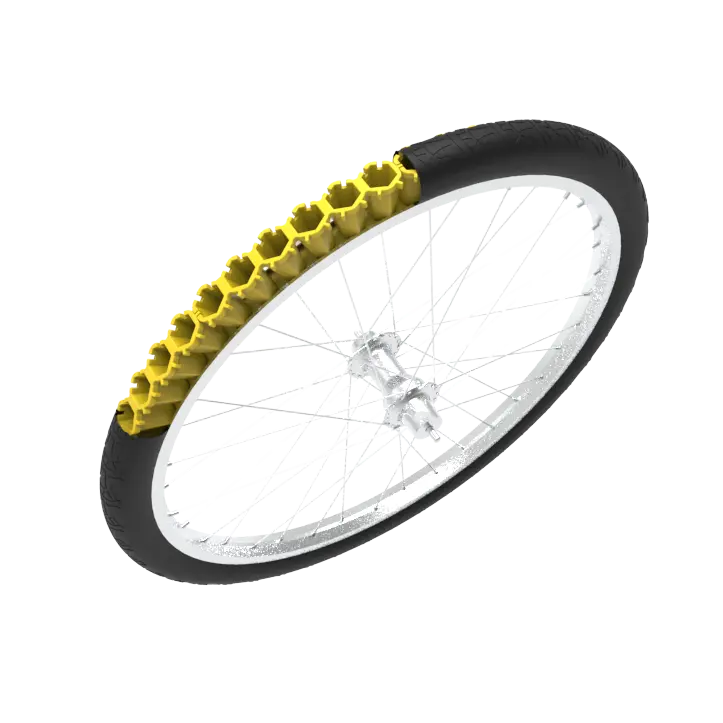

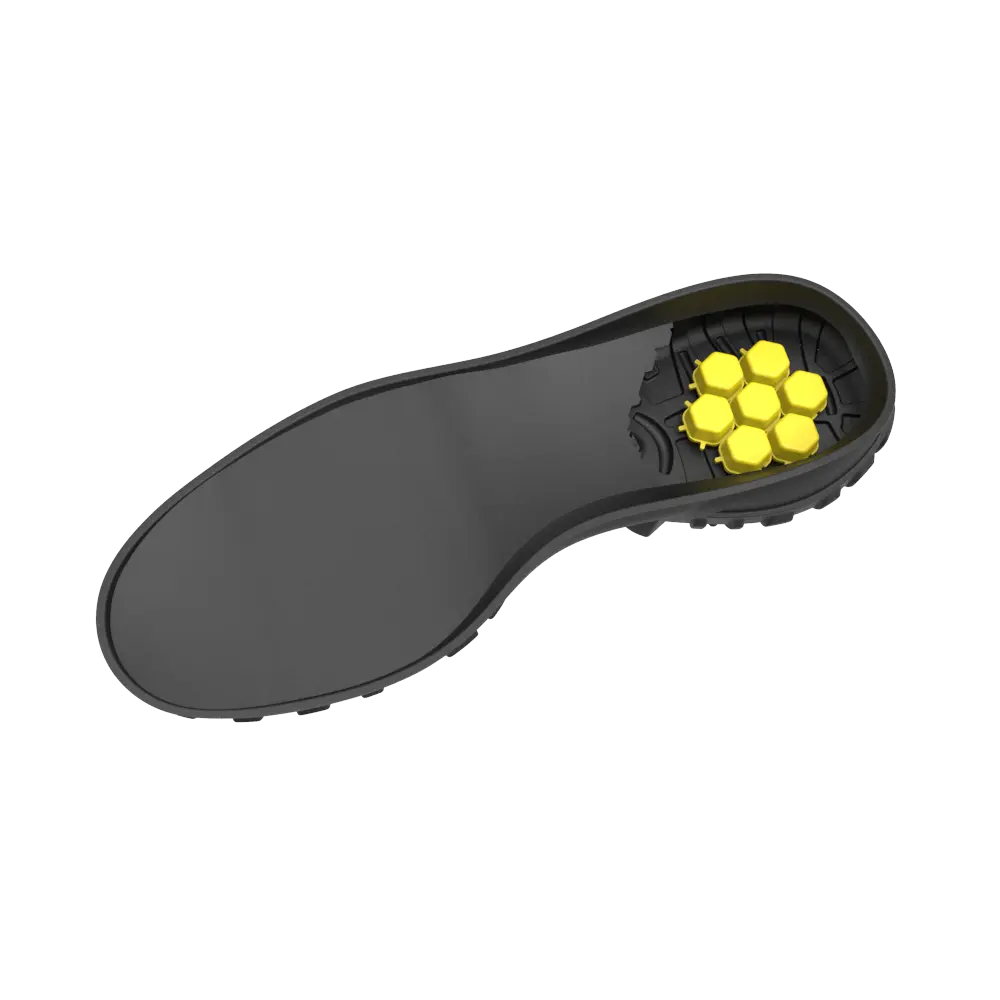

For the replacement of technical foams and the absorption of vibratory shocks, Hexaflex is a new innovative and efficient solution. Hexaflex is flexible, fully articulated and much more: it is insensitive to water and self-ventilated, is recyclable and sustainable. This flexible material does not emit VOCs and formaldehyde. And as a bonus, Hexaflex is made in France on our premises. In fact, it is an innovative and effective material for your most creative projects. Hexaflex has many possible applications and our design office will be happy to study them with you. Hexaflex technology is so special and interesting that we have protected it with patents in Europe, China, and USA (WO 2014 079 839) Consult the patent under this link

on the right : understand Hexaflex in 3D

Replacement of technical foams

and damping of vibratory shocks

Hexaflex : benefits

Understand Hexaflex in action

Standards and results

Standards compliance: Hexaflex

| Thickness Hexaflex | Standards compliance | Results |

| 18mm* | EN 1621-2 Level 2 | 5,5kN |

| 15mm | EN 1621-2 Level 1 | 12kN |

| 10mm | EN 1621-1 level 1 | 22kN |

| 15mm | EN 14404 | 2,3kN |

| 15mm | EN 15613 | 1,6kN |

| 7mm* | EN 13594 | 3,8kN |

* only available as a prototype